Flexible self-adhesive plinth oak gold SW-00000075

PPP skirtingPlinth made of porous polypropylene is a decorative element installed along the bottom of the wall to cover the joint between the wall and the floor. Thanks to its adhesive base, it is easy to install without the use of additional materials and is an ideal addition to various interior solutions.

Material: porous polypropylene (PPP)

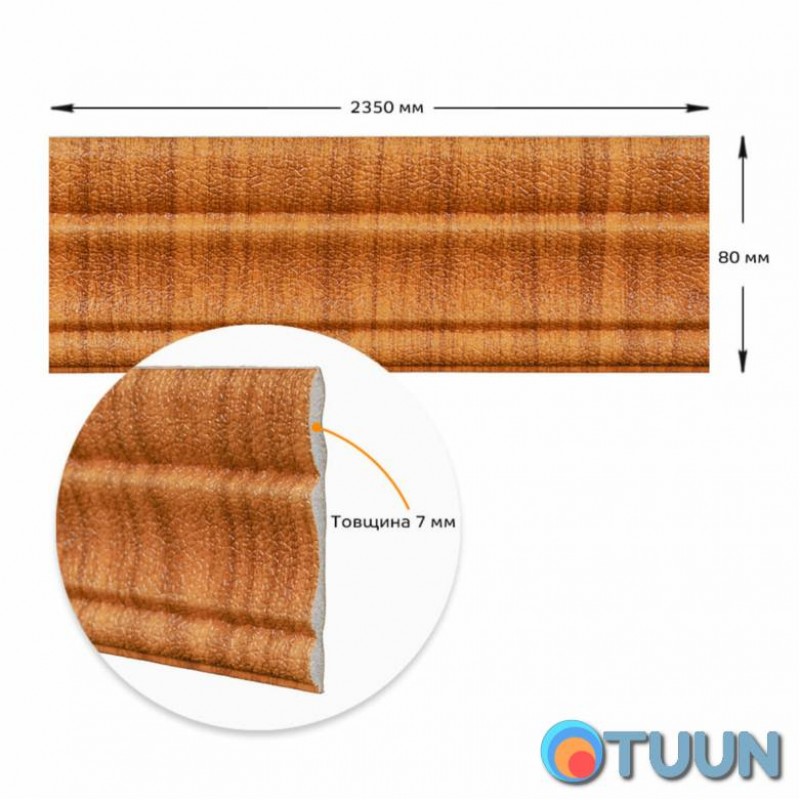

Dimensions: 80 x 2350 x 7 mm

Texture: embossed, matte surface

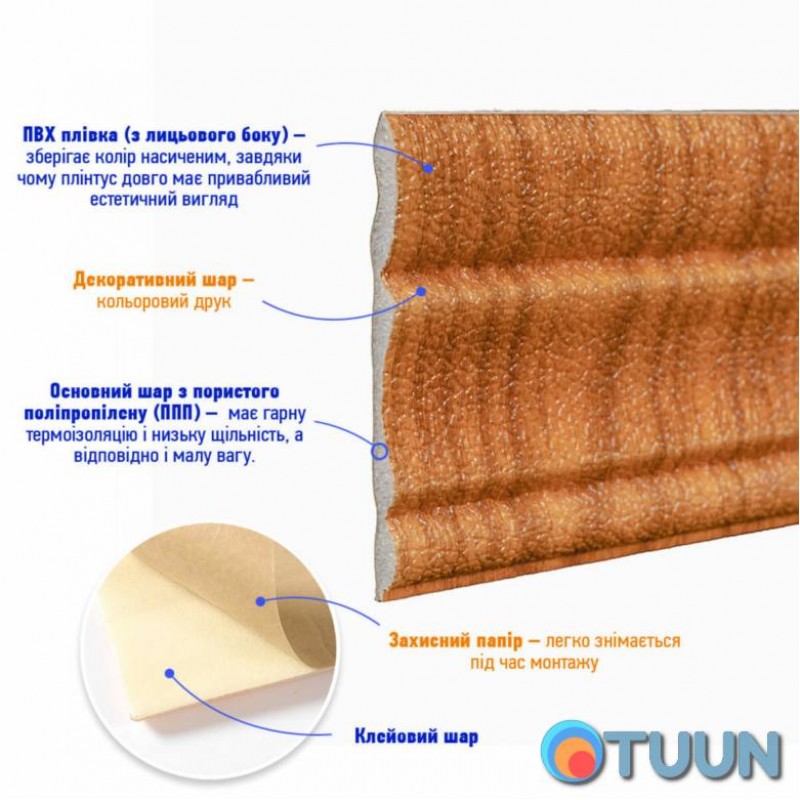

The plinth consists of the following layers:

- PVC film (on the front side) is a polymer consisting of long chains of vinyl chloride molecules that contain chlorine atoms, this makes the material resistant to chemicals, and due to the amorphous structure, PVC is very elastic, has low weight and resistance to mechanical damage.

- Decorative layer: high quality color printing that retains its saturation for a long time.

- The core layer of cellular polypropylene (CPP) is a thermoplastic polymer, its structure includes repeating molecular units of propylene. The structure of PPP is cellular, due to which the material has good thermal insulation and low density, and, accordingly, low weight. Porous polypropylene is also moisture resistant and chemically inert.

- Foil layer: the main property of this layer is the reflection of heat waves, which allows minimizing heat losses, thereby improving the thermal insulation of the room.

- Adhesive layer: non-toxic base with a high level of adhesion.

- Protective film – protects the adhesive layer from drying out and contamination, and can be easily removed during installation.

Manufacturing process:

- The first stage is the preparation of polypropylene. Using special equipment, raw materials are mixed in the form of granules or powder with antistatic additives and stabilizers that prevent the destruction of the polymer under the influence of external factors.After mixing, an agent is added to the mixture, which ensures the process of foaming the material when heated to 240ºC. As a result of heat treatment, many small balls are formed, which are then fused into a single mass under the influence of hot steam. The material takes its final shape during the extrusion process. Polypropylene undergoes an extrusion process, during which the heated plastic material is forced through an extruder (extrusion machine) using a screw mechanism. This allows the material to be formed into a suitable shape as a flat profile for skirting boards. The resulting porous polypropylene strips gain strength and rigidity within two days during complete polymerization.

- The second stage is the production of plinths. Strips of porous polypropylene are processed to create reliefs and patterns. This step may include thermal or mechanical treatment. At this stage, the plinth is covered with PVC film on the front side. This is followed by applying an adhesive layer to the back side of the baseboard, ensuring strong adhesion to the wall surface. The adhesive layer is covered with a protective film. Treated skirting boards are cut to final sizes and packaged for subsequent transportation and storage.

Application:

suitable for interior finishing work: decoration and walls in all types of residential and commercial premises, as well as for decorating furniture, doors and other flat surfaces.

Temperature range: Porous polypropylene can withstand operating temperatures from -20°C to +60°C.

Properties and advantages of the material:

- Easy installation: The self-adhesive layer makes the installation process quick and simple, without requiring additional materials or specialists for installation. The material is laid joint to joint, it can be cut with scissors or a mounting knife, it does not diverge between strips, does not swell or deform.

- Resistance to water and chemicals: porous polypropylene has good resistance to moisture, this makes it possible to use it in rooms with high humidity, and thanks to the protective PVC film, the panel can be used with household detergents (without using brushes with high abrasive ability).

- Insulation properties: the porous nature of the material, in addition to its low weight, gives it good heat and sound insulation properties.

- Flexibility and strength: The flexibility of the material allows it to adapt to different, even not very smooth surfaces, while maintaining strength.

- Environmentally friendly: Polypropylene is odorless and is a safe and environmentally stable material that can be recycled.

Calculation of the required amount of material:

- Measure the length of the surface to be pasted; to do this, you need to calculate the perimeter of the room. For example, the lengths of the walls of the room are 5.60 m and 3.20 m, then the perimeter of the room P = 5.6*2+3.2*2=17.6 m.

- The resulting perimeter must be divided by the length of one plinth (2.8 m) and rounded up: 17.6/2.8 = 6.28 rounded to 7 pcs.

- During the installation process, waste may arise due to trimming the baseboard, so it is recommended to add 1-2 strips to the calculation.

Installation instructions:

Surface requirements

For successful installation of adhesive-based plinths, the surface on which they will be installed must be:

- clean (free from dust, dirt, grease and other contaminants);

- smooth, without noticeable irregularities or cracks (if necessary, use putty or putty);

- dry (moisture can affect the adhesive base and its adhesive properties);

- heat, from 18ºС to 25ºС (for better adhesion of the adhesive layer to the surface);

- free from fungus and mold;

- without old wallpaper or other decorative elements;

If the wall has been painted or covered with any other material, a primer coat is required to ensure good adhesion.

Installation:

- It is necessary to make sure that the surface on which the skirting boards are intended to be glued meets the requirements listed above. There should be no drafts in the room during installation work.

- Gradually begin to remove the protective film on the back of the baseboard to expose the adhesive surface.

- It is necessary to start installation from one corner and carefully press the baseboard to the surface, ensuring that it is installed evenly and neatly, avoiding the formation of bubbles or wrinkles.

- The baseboard can be cut using a utility knife or scissors to adjust it to size, especially along the edges and corners of the surface.

- The baseboard must be pressed firmly against the surface by hand or with a rubber roller to ensure good adhesion between it and the base.

- Plinths cannot be re-glued.

Care instructions:

Do not use brushes and sponges with abrasive properties, or detergents with a high concentration of alkalis or acids. To remove dirt, it is better to use textile or viscose wipes using mild household chemicals.

There are no reviews for this product.

There are no reviews for this product, be the first to leave your review.

No questions about this product, be the first and ask your question.