Laminated self-adhesive film with foil base

Laminated self-adhesive film - is a thin, flexible, tear-resistant material that is coated on one side with an adhesive layer. This material is used for cladding, protection, decoration or restoration of smooth surfaces.

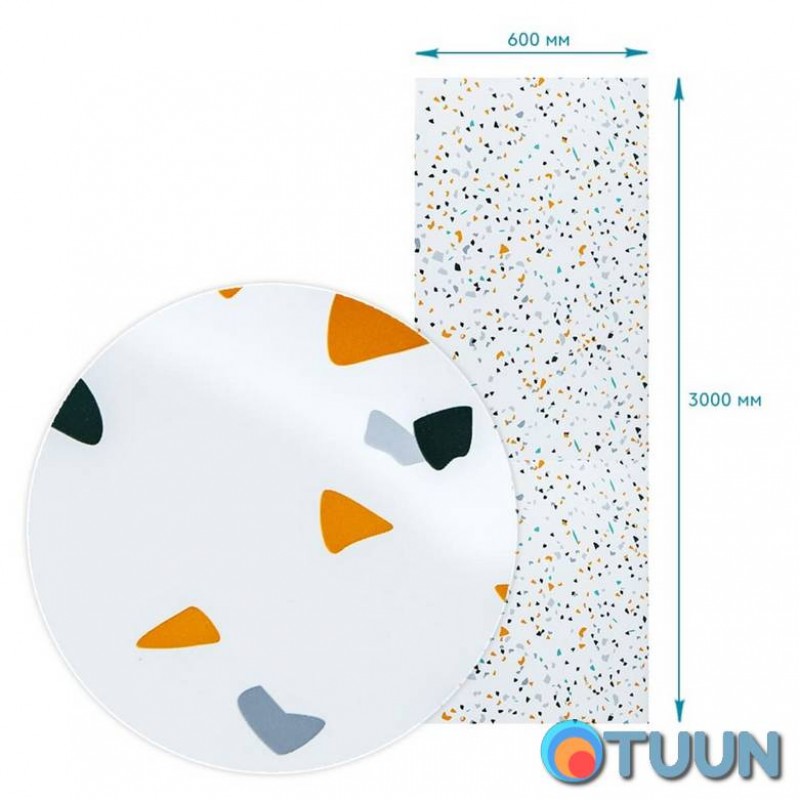

Dimensions: 600x3000mm

Coverage area: 600x3000 – 1.8 m²

Texture: has no relief, the surface is glossy

The film consists of several layers, each of which performs specific functions:

Laminated layer – the top layer that protects the film from scratches, stains and moisture. The laminated layer gives a glossy look and also ensures easy cleaning of dirt. The laminated layer is applied using a low-temperature lamination method, which uses a film with an adhesive base that is activated at a moderate temperature (usually 30-50°C). The film passes through special rollers that heat it to a level sufficient for reliable adhesion to the base material, but without the risk of deformation. This method is ideal for thin and temperature-sensitive materials, such as 0.05 mm thick film, providing uniform protection and durability of the coating. Decorative layer. Under the lamination there is a layer with a decorative print, which depicts a pattern or texture imitating wood, marble, tiles or other materials. This layer gives the film a visual appeal suitable for a variety of interior solutions. The foil layer provides the film with increased strength, making it more resistant to tearing, moisture and temperature changes. In addition, the foil provides a reflective effect, which makes the surface brighter and more stylish. The adhesive layer is a non-toxic base with a high level of adhesion, which ensures reliable adhesion. Protective siliconized paper – covers the adhesive layer before installation. It prevents accidental adhesion of the film, protects the adhesive layer from drying out and contamination, and is easily removed during installation. Marking on the back surface of the protective paper will simplify cutting the material. Application: the film is ideal for interior finishing works, such as decorating and cladding surfaces in residential premises (kitchen, living room, children's room, bedroom, hallway) and commercial spaces (offices, reception areas, shops, beauty salons, fitness centers), for updating furniture, doors and equipment.

Properties and advantages of laminated self-adhesive film:

Increased strength: thanks to the foil base, the film has high tear resistance - it is almost impossible to tear without a preliminary cut. This ensures durability and simplifies installation. Wear resistance: The laminated layer provides effective protection of the surface from scratches, stains, dust and dirt, which helps to preserve its original appearance. Thanks to this, the laminated film remains smooth and attractive even with intensive use, and is also easy to clean from dirt, which prolongs its service life. Moisture resistance: thanks to lamination, the film has increased resistance to moisture, which makes it ideal for use in rooms with high humidity, such as a kitchen or bathroom. High adhesion: the adhesive layer provides reliable adhesion to various surfaces such as metal, glass, plastic and laminated wood, making the film a universal solution for decoration, protection and restoration. Resistance to external conditions: The film withstands the influence of ultraviolet radiation, which protects it from fading and allows it to maintain color saturation for a long time, even under conditions of intensive use. Thin and flexible: Due to its thin thickness, the film is easy to form and is suitable for application to complex or curved surfaces, ensuring precise adhesion. Wide selection of designs: A wide range of textures, colors and designs allows you to choose the optimal solution for any interior or style. Requirements for surfaces

For successful installation of laminated self-adhesive film, the surface on which it will be installed must be:

clean (free from dust, dirt, grease and other contaminants); smooth, without protruding particles, unevenness or cracks (if necessary, use putty or filler); dry (moisture can affect the adhesive base and its adhesive properties); heat, from 18º to 25ºС (for better adhesion of the adhesive layer to the surface); no fungus or mold; without old wallpaper or other decorative elements; ! Film on an adhesive base, not suitable for rough or damaged surfaces and for brick walls.

Editing:

It is necessary to make sure that the surface on which the film is supposed to be glued meets the above requirements. There should be no drafts in the room during installation work. Each roll should be checked for color (shade) compliance before installation. Without removing the protective film from the adhesive layer, apply a new roll to the already pasted film; if the shade is different, turn the roll over. Remove the protective film from the back of the roll to expose the adhesive surface. It is necessary to start installation from one corner and gently press the film onto the surface, ensuring that the sheet lies flat and neatly, avoiding the formation of bubbles or wrinkles. The film must be smoothed out using a soft cloth or a special spatula. The film cannot be re-glued. Care instructions:

It is not advisable to use brushes and sponges with abrasive properties, detergents with a high concentration of alkalis or acids. To remove dirt, it is better to use soft textile or viscose napkins with the use of ordinary household chemicals.

Wall stickers, Sticker Wall