POLYURETHANE PANELS

Polyurethane tiles are wall coverings designed for interior decoration. The polyurethane layer on the surface of the tiles creates a 3D effect imitating ceramic tiles. For ease of joining, the tiles can be shaped like a puzzle or a square.

Material: polyurethane PU, polyethylene terephthalate PET in combination with polyethylene PE

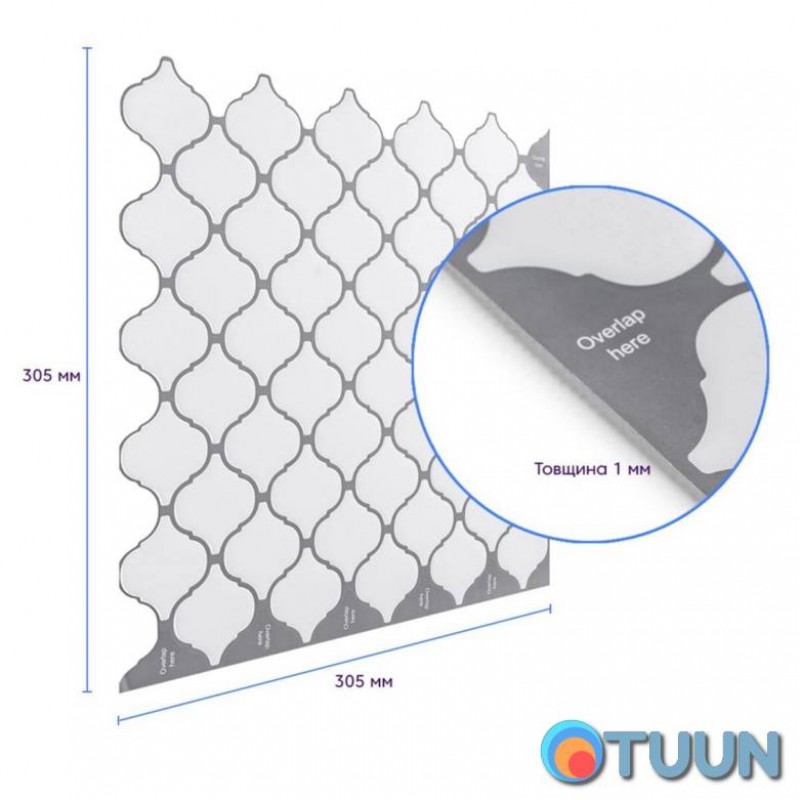

Dimensions: 305 x 305 x 1 mm

Weight: 88 g

Coverage area: 305 x 305 mm – 0.09 m²

Texture: imitating ceramic tiles/mosaics, glossy surface

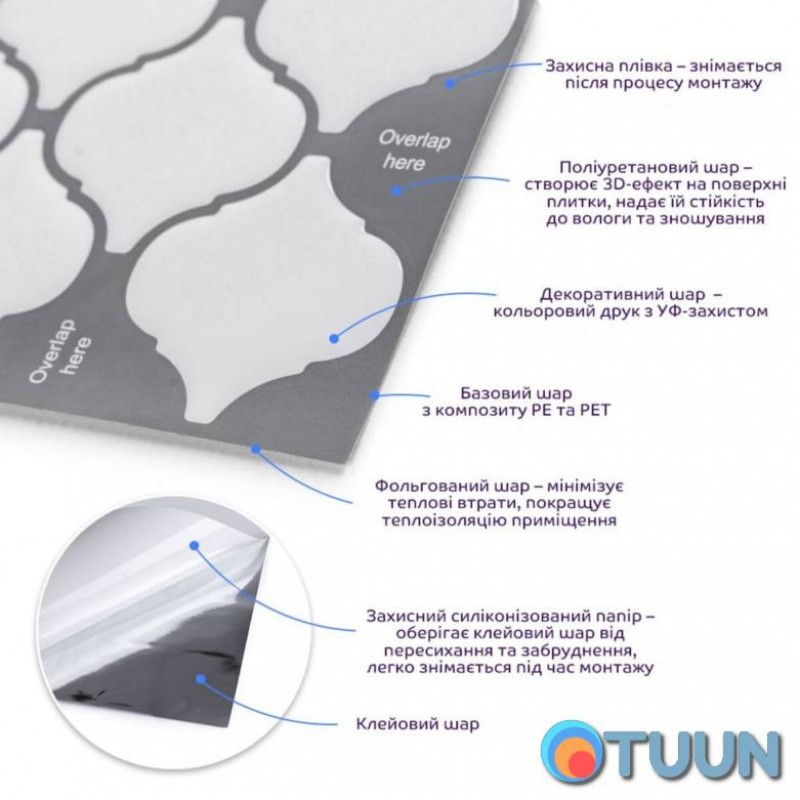

The tile consists of the following layers:

Protective film: protects the polyurethane surface from scratches, chips, and other mechanical damage during transportation. After installation, the film is removed from the surface of the tile. Polyurethane layer: creates a 3D effect on the surface of the tile. Polyurethane is a polymer that is formed by chemically combining isocyanate and polyol, resulting in a segmented molecular structure. Decorative layer: high-resolution color printing that imitates the texture of ceramic tiles and partially natural materials, thanks to a clear and detailed image, and UV protection helps prevent fading, keeping the color rich. PET base layer: a mixture of polyethylene terephthalate (PET) and polyethylene (PE) - a material consisting of repeating molecular units of ethylene glycol and terephthalic acid, has an amorphous structure, due to which the material is heat-resistant (up to +75º C), resistant to abrasion and moisture. Polyethylene (PE), present in the composition with polyethylene terephthalate (PET), gives it resistance to chemicals and mechanical damage, while the material remains elastic. Foil layer: the main property of this layer is the reflection of heat waves, this allows to minimize heat loss, thereby improving the thermal insulation of the room. Adhesive layer: non-toxic base with high adhesion level. Protective siliconized paper: keeps the adhesive layer from drying out and getting dirty, easy to remove during installation. Application: interior finishing works: decorating walls in all types of residential premises (kitchen, living room, children's room or bedroom, entrance area) and commercial premises (office premises, reception areas, shops, beauty salons or fitness centers), decorating furniture, doors and other flat surfaces.

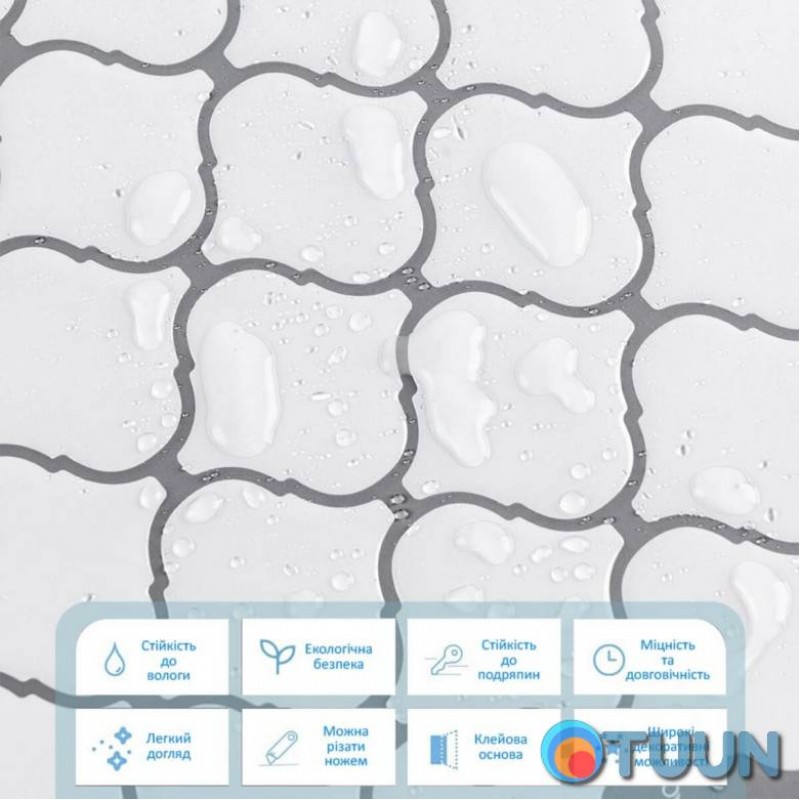

Properties and advantages of the material:

Easy installation: the self-adhesive layer makes the installation process quick and easy, without the need for additional materials or specialists. The material can be cut with scissors or a utility knife, and does not diverge, swell or deform between the strips. Moisture resistance: polyurethane tiles are moisture resistant, making them an excellent choice for bathrooms, kitchens and other rooms with high humidity; the material is also resistant to steam and mold. Durability: The strength and wear resistance of polyurethane allows the tiles to remain in their original condition for a long period of time. Aesthetic component: a wide choice of designs and colors allows you to choose a coating that matches your style and interior, it combines very well in terms of color scheme, allowing you to create your own interior design. Easy maintenance: polyurethane is easy to clean and does not require special cleaning agents. If an individual tile is damaged, you can easily replace it without the need for major repairs. Environmentally safe: polyurethane tiles are made from renewable resources, and the material itself is safe for health and the environment. Calculation of the required amount of material:

Measure the length and width of the surface to be pasted. Multiply the length by the width of each surface in meters and add the results together to get the area. For example, after measuring you got:Wall length 3.2 m.Wall width 0.8 m. 3.2*0.8 = 2.56 m² The resulting area must be divided by the area of one tile (305*305= 0.09) and rounded up: 2.56/0.09=28.44 rounded up to 29. During installation, waste may occur due to cutting tiles, so it is recommended to add 2-3 spare tiles to the calculation. Surface requirements:

clean (free from dust, dirt, grease and other contaminants); smooth, without protruding particles, noticeable irregularities or cracks (if necessary, use putty or filler); dry (moisture can affect the adhesive base and its adhesive properties); warm, from 18º to 25ºС (for better adhesion of the adhesive layer to the surface); no fungus or mold; without old wallpaper or other decorative elements; If the wall has been painted or coated with some other material, a sealer or primer coat will be required to ensure good adhesion. The primer should be applied at least 4 hours before installing the tiles.

Installation instructions:

It is necessary to make sure that the surface on which the polyurethane tiles are supposed to be glued meets the above requirements. There should be no drafts in the room during installation work.

Using a level, draw at least one vertical and one horizontal reference line to serve as a guide for tile placement. To get a straight edge, you should cut off the protruding parts on the first tile, preferably without removing the protective paper from the adhesive layer. Tiles should be installed in one direction. Remove the protective paper from the back of the tile to expose the adhesive surface. You need to start installation from one corner and gently press the tile onto the surface, making sure that it lies flat and neat, avoiding the formation of bubbles or wrinkles. To cover corners, the tiles must be trimmed. It is recommended to remove the protective film from the polyurethane layer only after installing the tiles. Care instructions:

Do not use brushes and sponges with abrasive properties, detergents with a high concentration of alkalis or acids. To remove dirt, it is best to use soft textile or viscose napkins with the use of gentle household chemicals, without peeling particles.

Self-adhesive films, Sticker Wall